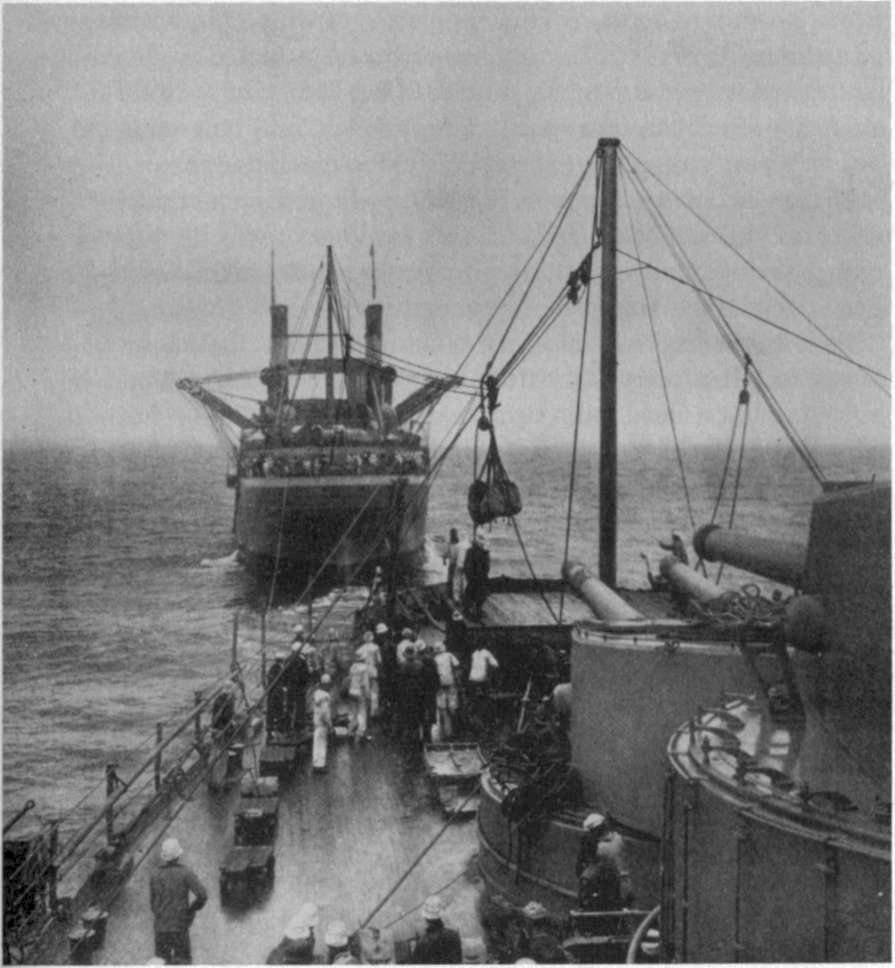

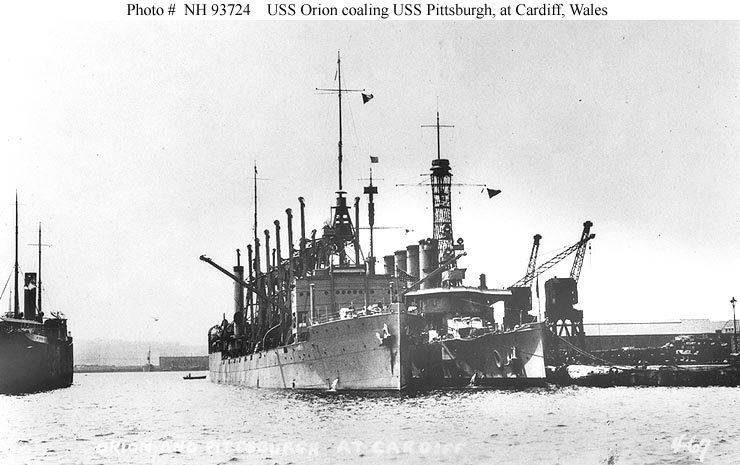

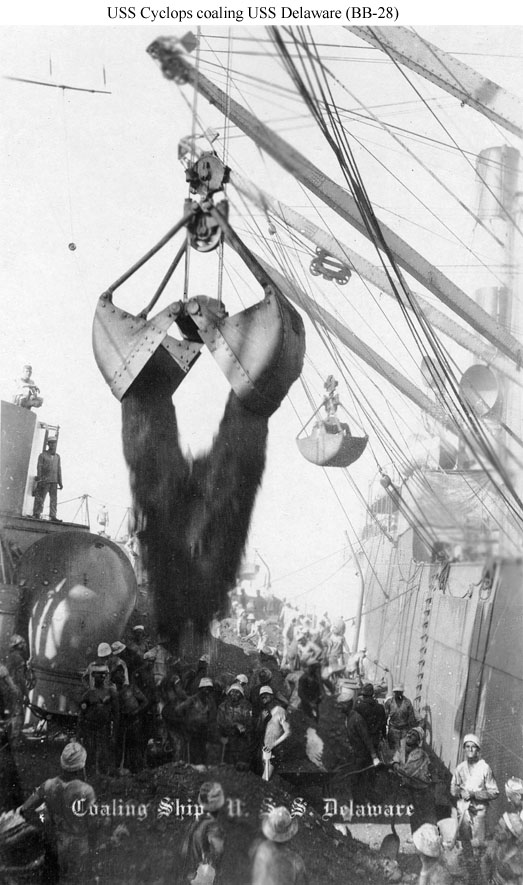

Coal and coaling

Posted: Sun Apr 26, 2020 1:42 am

Bunting Tosser wrote:Sun May 01, 2011 10:30 pm Generally, ships would have different grades of coal with varying burning properties; "best" (usually Welsh coal) would be saved for high speed work and the rest for normal working. Coal for immediate use would be near the boilers, the rest would be stowed around the ship. There were storage bunkers along the ship's sides where, in theory, the coal could act as additional protection for the engine room. Obviously the coal had to used "sensibly" from both sides to avoid a list developing. The bunkers were long corridors so when the coal had been cleared from the access point, more had to be shovelled from further down the corridor. As the coal was used up it had to be fetched from further along so there would be a chain of trimmers to move it. Confined space, dusty coal ...

Ah, "trim" - to keep balanced. It would be the chief stoker who would determine how the coal was used and also the amount of water taken into ballast tanks to assist balance.

erm, I think that's it.

Bunting Tosser wrote:Mon May 02, 2011 12:05 pm I knew the general principles but they were kindly fleshed out by Charles, see below. Naturally, I simplified it out of deference to the abilities of my audience. ::)

http://www.worldnavalships.com/forums/s ... php?t=4157

"Here is something I wrote for another forum on Stokers and Coal.

The Royal Navy didn't have Trimmers just Stokers, who were an all encompassing Marine Fireman. The Stoker was trained in the loading, distribution, storage and use of coal. The basics of a Royal Navy steam propulsion system that uses coal, has to use three compartments firstly the bunkers where the coal was stored, then the stokehold where the coal was held until required to be sent down chutes to the boilers.

Bunkers where strategically placed around the ship and used as extra armour by being placed between the outer skin and the boiler/engine rooms, so usually long thin compartments. Coal also came in different grades and calorific values the lower values being used for normal cruising, the higher saved for exercise or battle and stowed near the stokehold (Welsh coal being the preference).The location of coal within the ship would effect the ship's "trim" (i.e., if all of the bunkers on one side of the ship were emptied, she would lean drastically to one side), so the use of coal was monitored to keep the ship in trim. This was supervised by the Chief Stokers and their tanky's the water used to feed the boilers was also a large part of this equation both in what was used and what was produced.

As you could imagine during normal cruising this was a calm steady process, well oiled and managed by the Chief Stoker with Stokers manning or managing the three parts of ship, this gave the younger Stokers time to train and perfect their skills. A large ship would use 500 tons of coal a day under normal cruising conditions, three times that if on exercise or in battle conditions.

The bunkers were hot, often humid, and the air thick with coal dust. Each bunker had to be periodically emptied totally and the build up of dust cleaned out to stop the chance of spontaneous combustion, caused by the coal absorbing moisture and creating heat which would build up until the coal began to burn, a problem to put out usually done by flooding the bunker pumping out and then using the coal straight away.

Working within the bunkers was a terrible job. Since the coal bunkers could be long, men had to shovel the coal around in the bunkers, so that the bunkers could be filled evenly. When the coal was being used, a shovel relay would be set up in the bunkers, so that the coal in the bunker could be used evenly, and a ready supply kept at the entrance to the bunker for transfer to the stokehold. From this point it was shovelled in manageable quantities into the boiler rooms.

The job of 'Trimming' the bunkers was normally done by Sailors and Marines and the first place any army embarked where employed, this task was supervised by PO and Leading Stokers. The Stokers moving the coal from the stokehold to the boiler rooms and feeding the furnaces.

Regards Charles"

;D

dorbel wrote:Tue May 03, 2011 11:53 amNot sure about that one Charles, the cruisers that I have been logging use in the region of 85/95 tons a day on a passage and only take on 1,000 to 1,500 tons at a time when coaling. No doubt the battleships use more than that but your figure seems a bit high.A large ship would use 500 tons of coal a day under normal cruising conditions, three times that if on exercise or in battle conditions.

Bunting Tosser wrote: Yes, I wondered whether Charles had got his estimates a bit confused. That 500 tons could be expected for a "luxury liner" not a spartan warship. e.g. (admittedly an extreme example)

"2. That Titanic burned approximately the same amount of coal as Olympic at similar speeds.

Data is lacking, but on Olympic?s maiden trip she burned a total of 3,540 tons of coal, averaging 620 tons of coal per day at 21.7 knots; she arrived in New York with a reserve of some 1,300 tons, having departed Southampton with a mere 4,800 tons of coal. "

http://www.encyclopedia-titanica.org/di ... ?996334049